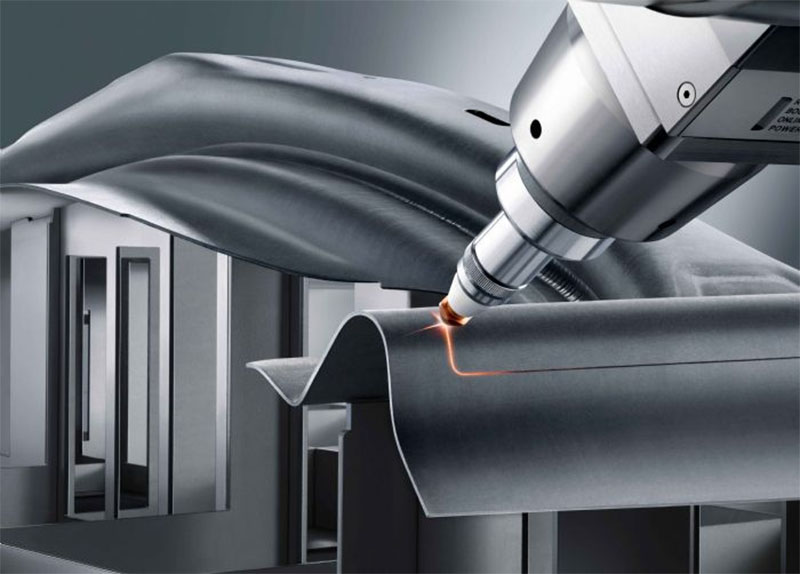

3D laser cutting metal is a high-end manufacturing process that utilizes a laser beam to make precise cuts in three dimensions. It offers a wider range of applications and greater manufacturing flexibility than traditional 2D laser cutting. The 3D laser cutting machine can work on any surface without manual angle adjustment.

The 3d laser cutting metal machine can move and rotate freely in three-dimensional space to realize the cutting of complex surfaces. Whether it is 3D engraving, cutting of irregular parts, or processing of complex structures including beveling, beveling, grooving, and opening, 3D laser cutting technology can easily deal with it.What Is 3d Laser Cutting?

The laser beam, focused through a converging lens, is directed onto the workpiece, rapidly increasing the surface temperature due to intense thermal energy. This rapid temperature rise causes rapid melting or vaporization at high temperatures. Simultaneously, the melted material is blown away by high-speed airflow, achieving the cutting objective as the laser head follows its trajectory. This technology enables precise cutting of various materials, including metals, non-metals, and composites. The entire process is controlled by CNC computer numerical control, providing high efficiency and accuracy.

According to the size of the user’s cutting and processing workpiece size as well as different, you can choose to program the robot side of the historical trajectory data for demonstration or offline programming, the robot’s six-axis loaded fiber laser cutting head for irregular workpiece materials to analyze the three-dimensional cutting. Fiber laser cutting head is equipped with a follower device and optical transmission control device, the use of fiber optic laser transmission to the cutting head, the different shapes and thickness of the plate for multi-directional cutting.3d Laser Cutting Applications for Metal

3D laser cutting machine is widely utilized in industries such as sheet metal processing, metalworking, advertising production, kitchenware, automotive, lighting fixtures, saw blades, elevators, metal crafts, textile machinery, food machinery, glass manufacturing, aerospace, medical equipment, and instrumentation. Particularly in the sheet metal processing industry, it has replaced traditional processing methods and is highly favored by industry development users.

Materials that can be processed include stainless steel, carbon steel, alloy steel, silicon steel, spring steel, aluminum, aluminum alloys, galvanized sheet, aluminum-zinc plated sheet, copper, silver, gold, titanium, and other metal structural sheets and pipes for cutting.

Pros. and Cons. of 3d Laser Cutter for Metal

3D 6-Axis laser cutting machine is widely used because the laser cutting machine has a common outstanding advantages and leading processing technology, which is the traditional cutting tools cannot be compared with the advantages. Three-dimensional laser cutting machine processing is characterized by fast speed, cut off the narrow, clean appearance of the kerf, heat-affected area is small, three-dimensional laser cutting machine in the processing not only improves the efficiency of the production and the quality of the cut pieces, to overcome the waste of materials in the original cutting processing methods.

High Efficiency

3D fiber laser cutting machine speed, high degree of automation, can greatly reduce the processing time and labor costs, is more than ten times the traditional cutting production efficiency, improve operational efficiency.

Precision Manufacturing

Fine processing technology, excellent precision, narrow cutting mouth, and small slit, able to carry out difficult processing and cutting of miniature parts, and greatly reduce the waste of tail material.

High-Quality Cutting Edge

Laser cutting smooth fracture, can save man-hours and labor costs, and do not need to repeat the processing can be used, play a very good production optimization.

Small Heat-Affected Zone

The heat-affected zone of three-dimensional laser cutting is very small, making the workpiece deformation is very small, the material around the slit is not affected, and the cutting quality of the product is good.

Wide Adaptability

Laser cutting can be applied to a wide range of materials, including metal, non-metal, composite materials and so on.

Three-dimensional laser cutting technology has many advantages, but there are also some disadvantages, such as:

High Cost

3D laser cutting systems usually require expensive equipment and high-performance lasers, making their investment cost relatively high. This may make it unsuitable for some applications with limited budgets.

High Maintenance Requirements

Maintenance of laser cutting systems can be complex, requiring regular calibration and repair. The performance and condition of key components, such as the laser, is critical to the quality of the cut and requires specialized personnel to maintain and service.

Limited Material Suitability

3D laser cutting can be challenging with some specialized materials. Some materials may reflect or absorb laser light poorly, affecting cutting results. And they may require more machine setup time prior to the cutting operation.

3D Laser Cutting Industrial Applications

Traditional CNC cutting machines can only handle two-dimensional plane, the 3D laser cutting technology to break this limitation. By adding 2 or more rotary axis, the 3d laser cutting metal machine can move and rotate freely in three-dimensional space to realize the cutting of complex surfaces. Whether it is 3D engraving, cutting of irregular parts, or processing of complex structures including beveling, beveling, grooving, and opening, 3D laser cutting technology can easily deal with it.

Automotive industry: The six-axis laser cutting robot adopts a mechanical arm structure and is equipped with a high-performance worktable. It mainly solves the problem of cutting holes and trimming the edges of hot-formed parts made of high-strength steel, and is widely used in automobile manufacturing, such as cutting and welding of body parts. Its high-precision and high-efficiency features make the automobile manufacturing process more accurate and faster.

Aerospace: In the aerospace field, laser 3D cutting technology in high-performance 3D laser cutting head is used to manufacture high-precision, high-quality parts, such as aircraft engine blades, rocket propellers and so on.

Electronics: In manufacturing in the processing of electronic products, laser 3D cutting technology can realize the accurate cutting of small parts, such as components on circuit boards, miniature sensors and so on.

New energy and metal shell: for example, lithium battery liquid cooling plate welding, household appliances metal shell and other large volume, high volume and consistency requirements for the manufacture of parts. Through programming and automation control, laser cutting robots can ensure uniformity in the production process, reduce human error and improve product quality.

Construction Materials: Heavy materials used in the construction industry are cut using laser tools for a variety of parts. For example, we can laser cut on thick metal plates and also for steel structures.

In the field of electronics manufacturing, laser cutters can cut and circuit boards hole drilling of electronic products. In addition, in the field of textiles, leather, and plastics, 3D laser cutting machines are also capable of cutting and engraving complex shapes for the production of clothing, shoes, and bags.3D Laser Cutting Technology Trends

Laser technology presents unique advantages, and in various fields, laser 3D cutting technology is undergoing continuous development and innovation. Its high precision, efficiency, and strong adaptability make it widely applied in industries such as aerospace, automotive, and electronics.

Upgrade in technology, improved accuracy:

As laser technology continues to advance, the precision of laser 3D cutting is also continuously improving. The new generation of automated 3D laser cutting employs more advanced control systems and algorithms, enabling more precise control over the laser beam’s path, speed, and power, thus achieving more accurate cutting results.

Increase in speed and efficiency:

While pursuing high precision, there is also a constant effort to increase cutting speed and efficiency. The new generation of laser cutting equipment utilizes more efficient laser generators and optical systems, making the laser beam’s energy more concentrated and stable, resulting in faster cutting speeds. By optimizing cutting paths and algorithms, cutting efficiency is further improved, effectively reducing production cycles.

Development towards intelligence:

With the rise of Industry 4.0 and smart manufacturing, laser 3D cutting technology is evolving towards intelligence and automation. The new generation of 3D laser cutting equipment is equipped with advanced sensors and control systems, capable of automatic material recognition and positioning, thus achieving unmanned and automated cutting production. This makes laser 3D cutting technology more flexible, able to meet diverse production needs, and expands its wide-ranging applications.

Expansion of new materials and applications:

With the continuous emergence of new materials, the application scope of laser 3D cutting technology is also expanding. The new generation of laser cutting equipment has broader material processing capabilities, covering various materials such as metals, non-metals, and composites, providing more extensive application possibilities for industries such as aerospace, automotive, and electronics. Meanwhile, with the development of new materials, laser cutting technology will further drive innovation and breakthroughs in these fields.

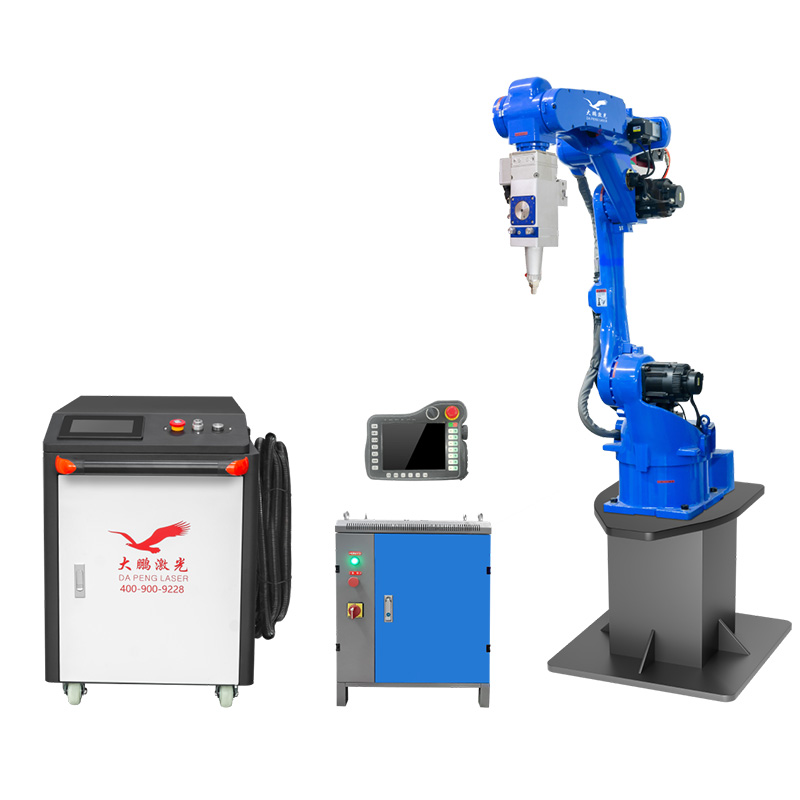

DAPENG 3D laser cutting machine has excellent precision and flexibility for irregular workpieces. It adopts laser beam for cutting, which is not limited by the size and shape of traditional cutting tools. It can easily complete the laser processing of various irregular workpieces, thus meeting the customized needs of complex shaped parts in different industries.

The 6-axis laser cutting robot enables the cutting machine to realize more diversified movements when processing irregular plates. By controlling the motion of six axes at the same time, the cutting machine can flexibly adjust the cutting angle and direction, making the cutting of irregular plates and pipes more flexible, precise and comprehensive.

DAPENG LASER has a wide range of metal fiber laser cutting systems, each with different features and attributes that make it more suitable for specific industrial applications. Our engineers and technicians can customize the suitable 3d laser cutter for metal. The right laser cutting solutions for your product. Get in touch with one of our engineers and we can make a free sample for you and you will be sure to receive a satisfactory sample.